Automatic Lubrication System

Product Details:

- Product Type Lubrication System

- Power Source Hydraulic

- Operating Type Automatic

- Usage & Applications Industrial

- Click to View more

Automatic Lubrication System Price And Quantity

- 1 Piece

- 600000 INR/Piece

Automatic Lubrication System Product Specifications

- Lubrication System

- Automatic

- Hydraulic

- Industrial

Automatic Lubrication System Trade Information

- Cheque, Cash Advance (CA)

- 1 Piece Per Month

- 2 Months

- loss packing

- All India

- ISO :9001 , 2008

Product Description

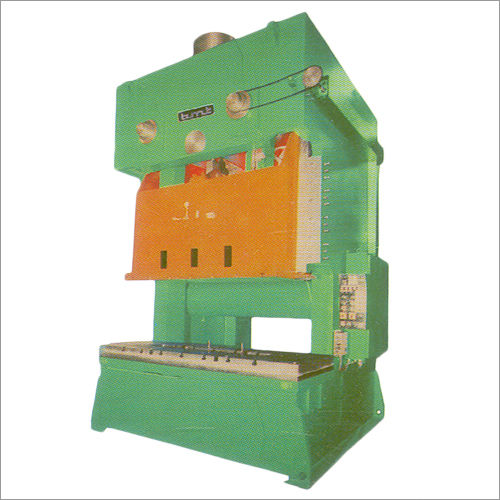

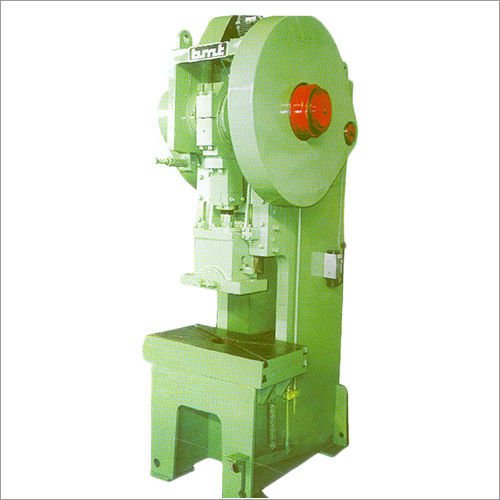

We are a well-established firm that has made its presence in the industry, by manufacturing and supplying Automatic Lubrication System. Our dexterous workforce uses quality grade mild steel and cast iron to manufacture this system. It is designed for universal stamping applications such as drawing, forming, blanking, piercing, bending and trimming. Hydraulic overload is installed inside the slide as an overload safety device to protect the machine from damage and convenience work. We offer Automatic Lubrication System at cost effective prices to clients.

Features:

- Robust construction

- Easy to operate

- Longer service life

Further Details:

BMX-series is a "C"-Frame open back single crank design for universal stamping applications such as drawing, Forming, Blanking, Piercing, Bending, Making, Sizing, Trimming,.... etc. Either in single strokes or continues mode.

BMX-series presses are constructed of fully stress relieved steel weldments, with Geared or Ungeared type drive having adjustable or fixed Stroke Length "Shear Plate" or "Hydraulic Overload" is adapted inside the slide as an overload safety device to protect the machine from damage and convenience work.

Two kinds of slide adjusting methods, by hand and by motor, are available. Pneumatic slide balancer keeps the slide balance and helps in smooth working of machine.

Air actuated Clutch and friction Brake mechanism is a combine type, low inertia unit giving great6er efficiency and is designed for trouble free production and low maintenance cost.

Main and connection Bearings are Phosporus Bronze Bushes. Clutch and Brake mechanism and drive shaft have antifriction bearings.

Automatic Lubrication at all points of wear with timer control.

Technical Specification :

|

Model BMX |

25 |

40 |

63 |

100 |

160 |

200 |

250 |

|

Force (kN) |

250 |

400 |

630 |

1000 |

1600 |

2000 |

2500 |

|

Rated distance Before B.D.C. (mm) |

3.5 |

4 |

5 |

5 |

6.3 |

6.3 |

6.3 |

|

Stroke Length (mm) |

8-80 |

8-88 |

8-100 |

8-125 |

20-160 |

20-160 |

20-160 |

|

Number Stroke (spm) |

70 |

65 |

60 |

45 |

40 |

40 |

35 |

|

Flywheel Energy (kJ) |

4.4 |

8.0 |

16.75 |

25.0 |

55.0 |

70.0 |

80.0 |

|

Shut height Over Bed (mm) |

300 |

315 |

350 |

450 |

500 |

560 |

560 |

|

Slide Adjustment (mm) |

63 |

70 |

70 |

80 |

125 |

125 |

125 |

|

Slide Area (mm) |

350x250 |

400x350 |

500x400 |

600x450 |

710x600 |

900x800 |

950x800 |

|

Bolster Area (mm) |

630x400 |

800x450 |

900x550 |

1000x630 |

1120x750 |

1250x800 |

1250x800 |

|

Main Motor (kW X rpm) |

2.2x1440 |

3.7x1440 |

7.5x1440 |

9.3x1440 |

15x1440 |

15x1440 |

18.5x1440 |

|

Height from floor to top of bolster (mm) |

800 |

900 |

900 |

900 |

900 |

900 |

900 |

|

Air Pressure Required (Kg/cm2) |

5.5 |

5.5 |

5.5 |

5.5 |

5.5 |

5.5 |

5.5 |

|

Approx. Machine Weight (kg) |

2250 |

3850 |

5900 |

9000 |

15000 |

20000 |

28000 |

|

Die Cushion |

DC-82 |

DDC-82 |

DDC-102 |

DDC-123 |

DDC-144 |

3DC-144 |

3DC-164 |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+